“ FTR Makina Kimya Metalurji A.Ş., 2003 yılından günümüze temsilcilik, distribütörlük ve özel imalat konularında başta çimento, maden, enerji santralleri, demir çelik, arıtma sektörü, otomotiv, beyaz eşya olmak üzere tüm sanayi kollarında faaliyet göstermektedir. Çözüm ortaklarımız, konularında dünya çapında bilinen markalardan oluşmaktadır. Tamamen mühendislerden kurulu teknik ekibimiz, satış öncesi, süreci ve sonrasındaki tüm gerekli hizmetleri sunmaktadır. ”

-

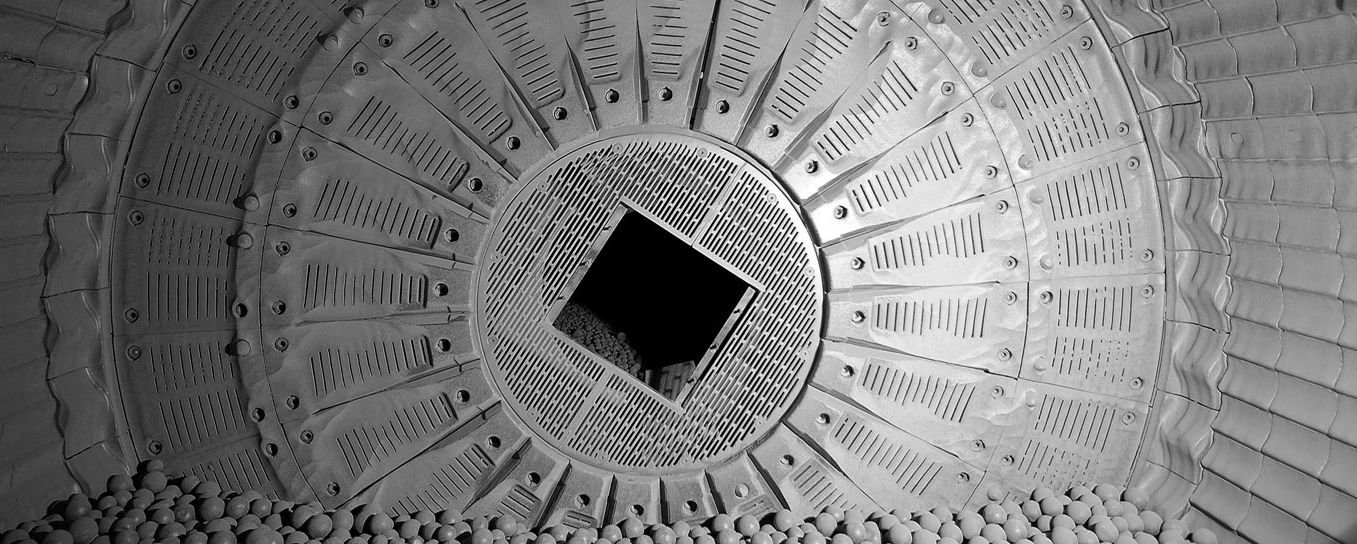

ARA DİYAFRAM

bilyalı çimento değirmenleri için...

-

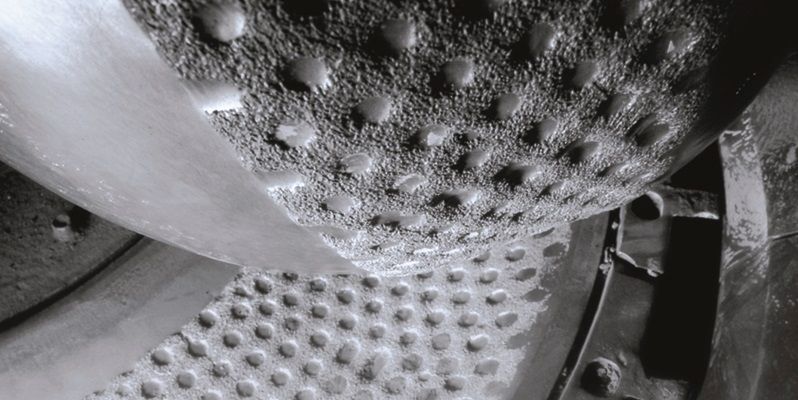

YÜKSEK KROMLU ÇELİK DÖKÜM BİLYALAR

öğütme prosesleri için...

-

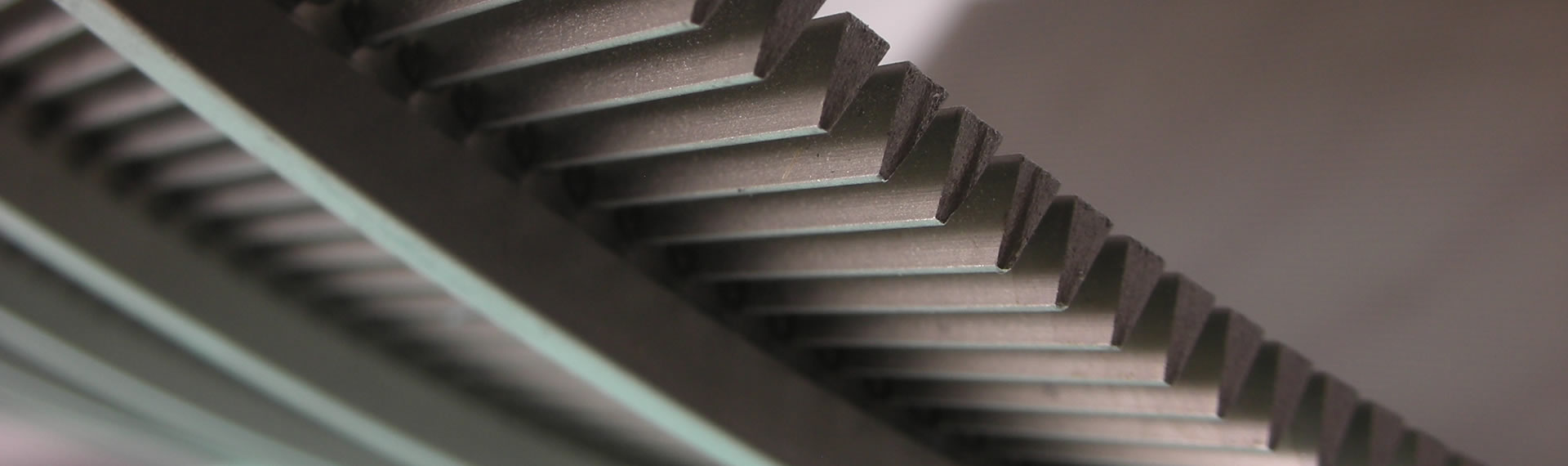

SERAMİK KOMPOZİT MALZEME

dik değirmen vals gömlekleri ve tabla segmentleri için...

-

SERAMİK KOMPOZİT MALZEME

dik değirmen vals gömlekleri ve tabla segmentleri için...

-

BİLYA TASNİF MAKİNASI

%100 TÜRKİYE'DE ÜRETİM

-

LASTİK PARÇALAMA - PRECIMECA

alternatif yakıt hazırlama...

-

XCC KOMPOZİT MALZEME ÇEKİÇLER

manganez çekiçlere göre 8 kata kadar daha uzun ömür...

-

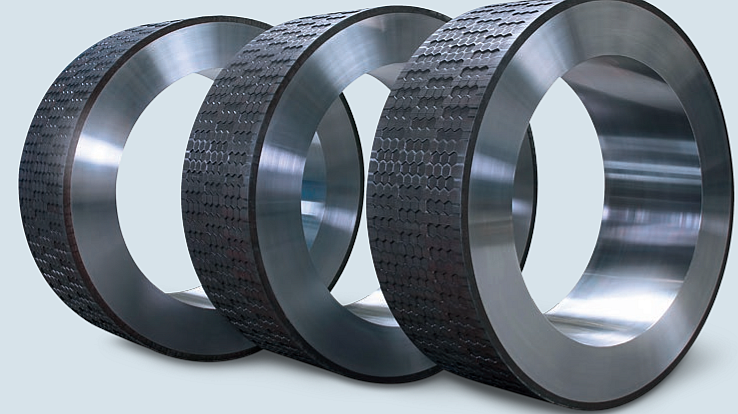

ROLLER PRESLER İÇİN HEXADUR MERDANELER

kaynak ve yüzey profilleme yapılmadan 70.000 saate kadar ömür...

-

PENDULUM KLINKER SOĞUTMA - IKN

problemsiz operasyon....

-

80.000 TİPTEN DAHA FAZLA ÇEŞİT

sprey nozulları ve aksesuarları...

-

TIKANMAZ ELEKLER

paslanmaz çelik elekler...

-

SERAMİK KOMPOZİT MALZEME

soğutma plakaları için...